Side loading and unloading of trucks is a common method. The forklift continuously drives around the truck to reach the goods on both sides. However, this method is risky due to the lack of an overview of the forklift’s position. Moreover, it takes extra time to load and unload all the goods because the forklift has to go around the trailer constantly.

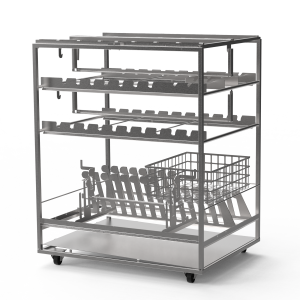

By using hydraulically extendable forklift forks, you can load and unload a truck or trailer from one side because the forklift forks can be extended from the cab. The big advantage is that productivity increases by ± 40%, and an average of 1 extra combination can be loaded and/or unloaded. Because the forklift remains on one side, the risk of accidents decreases because the forklift cannot suddenly appear from behind the trailer.

When loading and unloading trucks from one-side, the forklift is more visible and less likely to have accidents. This is because the forklift driver does not have to drive around it as often, significantly reducing the chance of collisions with other forklifts and bystanders.

One-side truck loading and unloading increases the efficiency by around ± 40%. A time study show that a forklift in combination with ReachForks can load/unload at least one (1) extra truck per hour. On the other hand, the truck can be unloaded/loaded faster and the cost of the forklift driver is saved.

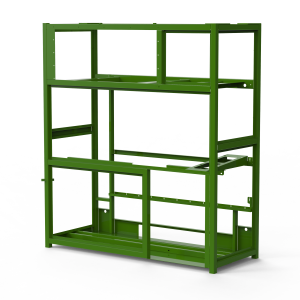

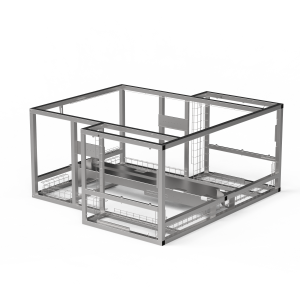

Because there is no longer a need to drive around the truck during side loading of trucks and trailers, additional space is freed up, at least about 70m². Storage space is expensive, and the freed-up space can be used for additional pallet storage, or one can already save in the design of the building.

A trailer holds an average of 33 euro-pallets (EPAL), which means that when using the “side-loading” method for 8 hours per day, 264 additional pallets can be handled. This is a huge improvement to the incoming and outgoing goods, allowing the customer to increase productivity and revenue.

Forklift trucks no longer circle trailer and truck combinations, creating more overview and peace when loading and unloading from one side. This has a positive effect on the overall efficiency and safety of the work floor. Side-loading in logistics is very common but can be more efficient with the use of ReachForks.

Because of the time savings in unilateral loading and unloading and improved safety, the forklift’s workload is reduced, less stressful situations arise, and the driver enjoys his job more. The truck driver joins in the fun because he can leave earlier and only has to open one side of the trailer curtains. Thus, working conditions during unilateral loading and unloading of trailers are improved.

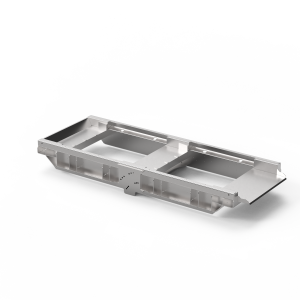

For putting pallets away, directly on the other side of the truck, a heavier forklift is necessary because the load is moving away from the forklift. This will move the load center of gravity further away from the forklift and will require more counterweight to rebalance. Your forklift supplier can give you more information on this.

A practical test has shown that when loading – (un) loading from both sides on one side, 3.4 trailers with 33 pallets can be handled in an hour while using hydraulically extendable forklifts, 4.8 trailers can be handled. This is an improvement of ± 41%. Because the driver finishes his work faster (saving costs) and or more pallets can be handled, the ROI is an average of one year.

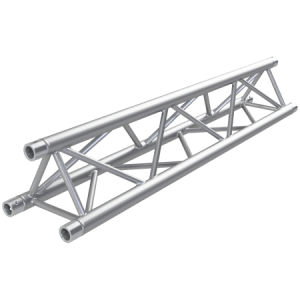

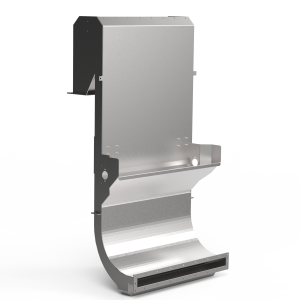

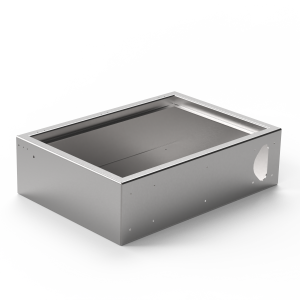

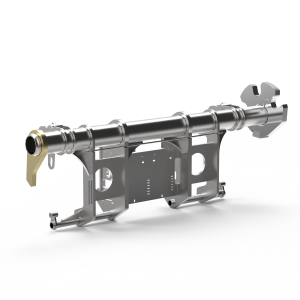

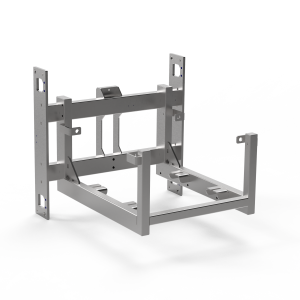

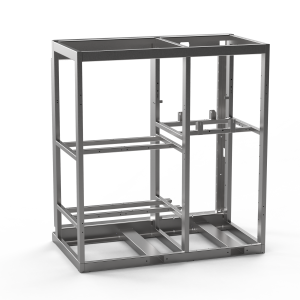

KOOI® ReachForks are extendable forklift attachments designed to extend your forklift reach, enabling easier and more efficient loading and unloading of trucks. The KOOI® ReachForks are developed in 1980 by Meijer Handling Solutions and can be manual and hydraulic.

Yes, they are adjustable and can accommodate various pallet sizes and configurations.

Studies and reports indicate that the use of KOOI® ReachForks can improve efficiency by up to ± 40%. This increase in efficiency is due to the ability to handle different pallet sizes quickly and the capability to load and unload from one side of the truck, minimizing the need for repositioning.

They are compatible with most standard forklifts, but checking compatibility with your specific model is essential.

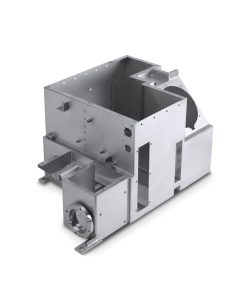

They are hydraulically controlled and operated from the forklift cabin, allowing precise control over the extension and retraction.

Yes, they are designed to lift and transport heavy loads, but it’s important to adhere to the specificed weight limits for your model. Capacities up to 30.000 kg/lc 600 mm (13.636lbs/24″) are possible.

When a pallet is pushed forward, the distance between the pallet and the forklift increases. This typically requires using a heavier forklift for one-sided loading and unloading. The reason is that the pallet’s center of gravity shifts, and the forklift needs to maintain balance with the extended pallet to prevent tipping. Additionally, the hydraulically operated extendable forks need a 4th function, which many forklift brands offer as a standard or optional feature. Therefore, it’s crucial to consult with your forklift supplier, who will likely be familiar with our KOOI® ReachForks since they are also supplied directly to most forklift manufacturers. If you need local assistance contact your local KOOI® Dealer: