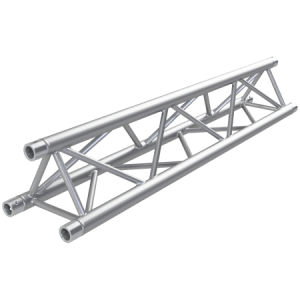

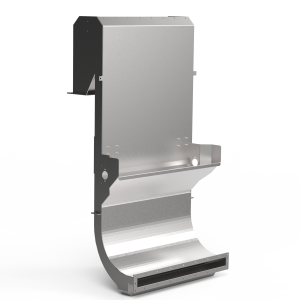

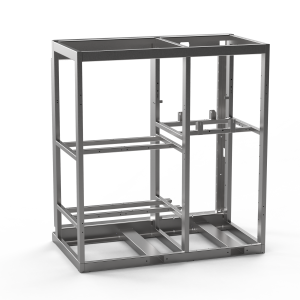

Hydraulic extendable forklift forks are designed to improve the functionality and efficiency of forklifts. The forks can be extended and retracted, allowing the operator to always adequately support pallets and or move pallets further away from the forklift over a certain distance. This feature improves load handling, increases operational safety and saves time by reducing the need for manual adjustments. Ideal for warehouses and distribution centers, these forks increase productivity and versatility.

Hydraulic ReachForks are used to extend the reach of forklifts, allowing them to handle loads in double-deep pallet warehouses. They are ideal for loading and unloading goods from trucks and efficiently managing palletized products of different sizes. These forks improve operational efficiency by reducing manual adjustments and increasing the speed of load handling. Commonly used in distribution centers, manufacturing facilities, and logistics operations, they enhance productivity and safety.

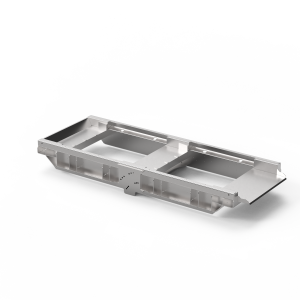

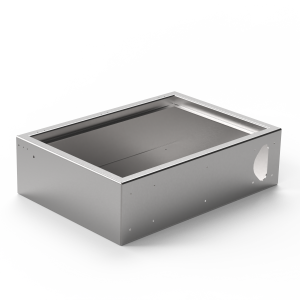

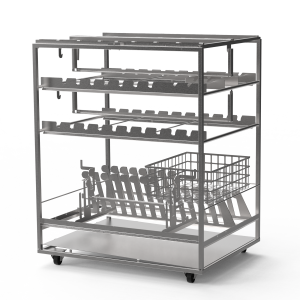

Depending on the application, telescopic forks generally provide sufficient support for various pallet types, reducing the risk of dropped loads due to forward tipping. This ensures greater safety and stability when handling different pallets.

Read more

In applications such as loading and unloading trucks, it is no longer necessary to drive around the trailer combination, saving 40% of time. For Euro pallet transport, shorter forks can quickly insert into a pallet and provide sufficient support when extended.

Read more

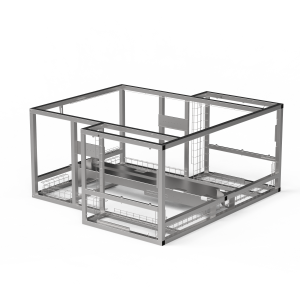

In cross-docking, a forklift can carry one or two pallets simultaneously to the designated zip-code location instead of one, achieving a time savings of at least 27%. Using telescopic forks for pallet loading can further reduce time by up to 37%.

Read more

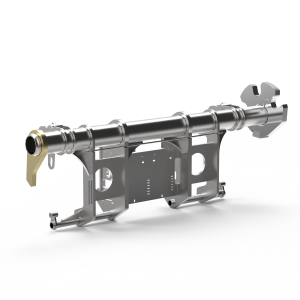

A forklift operator’s task is to transport pallets from A to B as efficiently, safely, and damage-free as possible. Reachforks, especially KOOI® ReachForks, are ideal for this, enhancing job satisfaction by making the operator’s work easier and more enjoyable.

Read more

Telescopic forklift forks improve productivity in all applications. For example, more trucks can be loaded in single-sided loading/unloading, and double-deep pallet storage allows for increased pallet in -and output.

Read more

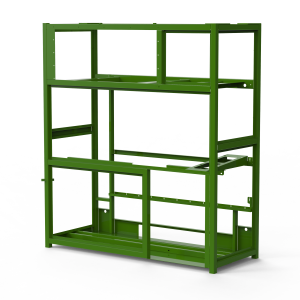

Double-deep pallet storage saves aisle space, allowing for more pallets to be stored. In single-sided loading and unloading, space is saved as the forklift doesn’t need to maneuver around the truck, maximizing storage and operational efficiency.

Read more

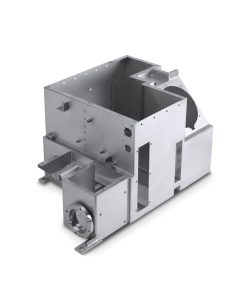

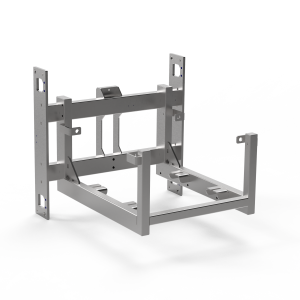

KOOI® ReachForks are hydraulic extendable forklift forks that allow operators to adjust fork length for better reach and load handling.

They enable quick adjustment of fork length, reducing the need for repositioning the forklift and speeding up load handling.

Yes, they enhance safety by providing precise control over fork extension, reducing the risk of load instability and operator injury.

They are ideal for warehouses, distribution centers, and logistics operations, particularly for handling pallets in deep or hard-to-reach spaces.

Yes, by adjusting to the correct fork length, they minimize the risk of damage to pallets and goods during handling.

They improve efficiency by allowing for faster, more accurate positioning of loads, reducing loading and unloading times.

Regular inspection and lubrication of the hydraulic system and moving parts are necessary to ensure optimal performance and longevity.

They are compatible with most forklift models, but it’s essential to check specifications to ensure proper fit and function.

Yes, they are designed for both indoor and outdoor use, though proper maintenance is required to protect against environmental wear and tear.

By reducing manual adjustments and providing precise control, operators can handle loads more efficiently, increasing overall productivity.