Since its inception in 1921, Roemmers has established itself as a leader in the Argentine pharmaceutical industry. The company’s dedication to quality has allowed it to achieve the prestige and significant market share it now enjoys. For over two decades, the company has been ranked first among national international pharmaceutical laboratories. Roemmers’ products treat a variety of health conditions including those of the coronary, digestive, respiratory systems, as well as psychiatric and neurological disorders and rheumatologic and infectious diseases.

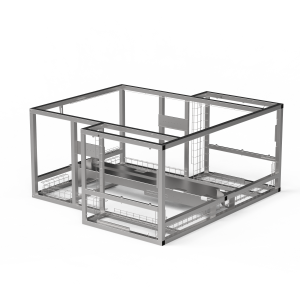

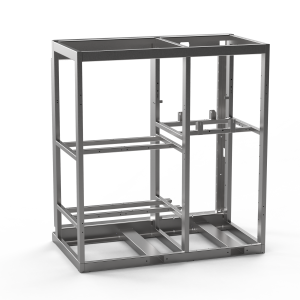

Roemmers pharmaceutical laboratories work under strict hygiene and sanitary regulations. They ensure full compliance with GMP (Good Manufacturing Practices) standards in all its production facilities, as well as with other quality and environmental protection standards. Production is made in a “clean” area were wooden pallets should be avoided and only sanitary plastic, aluminium or stainless steel pallets are allowed. Those pallets are very expensive and are not used for external transport. For this reason, Roemmers contacted Argentine RollerForks dealer Raypac and to investigate the possibilities of RollerForks.

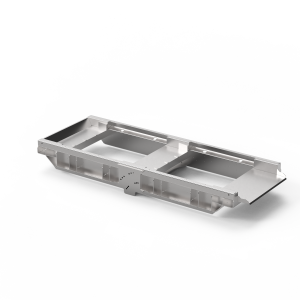

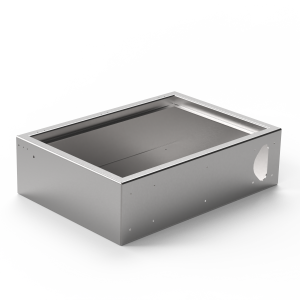

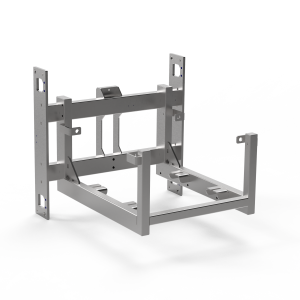

Once the medicines are blistered or bottled, they are packaged into tarpaulin boxes. Roemmers uses special plastic RF-Pallets with extra slats on the top surface. This makes it easier to position the RollerForks under the slipsheets. Once all boxes are palletized on slipsheets they are wrapped with shrink film.

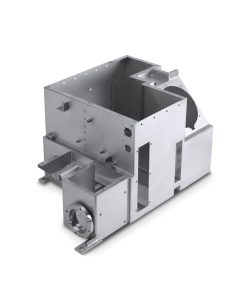

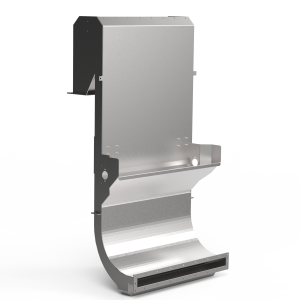

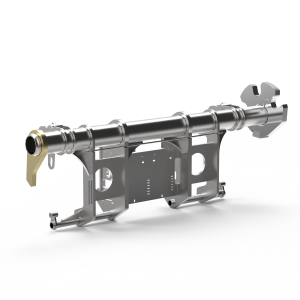

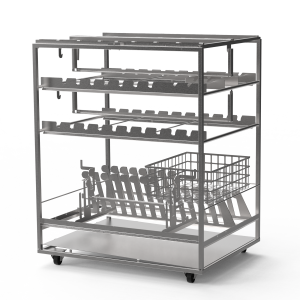

At this point, the plastic RF pallets are taken from the “clean” area and being transported to the pallet exchange area where the product will be removed with the use of RollerForks. The  RollerForks are mounted on a standard counterbalanced lift truck or on a Reach truck with pantograph system. The RollerForks fits perfectly between space of the synthetic slat and roll easily under the slipsheeted products. As soon the load is on the RollerForks, it can be transloaded onto the standard wooden delivery pallet in a very quick and efficient operation that takes less than a minute.

RollerForks are mounted on a standard counterbalanced lift truck or on a Reach truck with pantograph system. The RollerForks fits perfectly between space of the synthetic slat and roll easily under the slipsheeted products. As soon the load is on the RollerForks, it can be transloaded onto the standard wooden delivery pallet in a very quick and efficient operation that takes less than a minute.

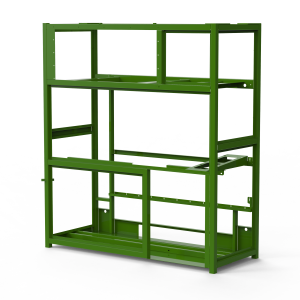

The plastic pallets will be sanitized to re-enter the production clean area and the palletized products on top of the wooden pallet is taken to the warehouse racks with the same forklift truck.

Roemmers also considered a pallet inverter, but this would have required more space and longer pallet exchange cycles. RollerForks proved an ideal solution because they could be mounted in the existing forklift trucks without any modification and can still move standard pallets.