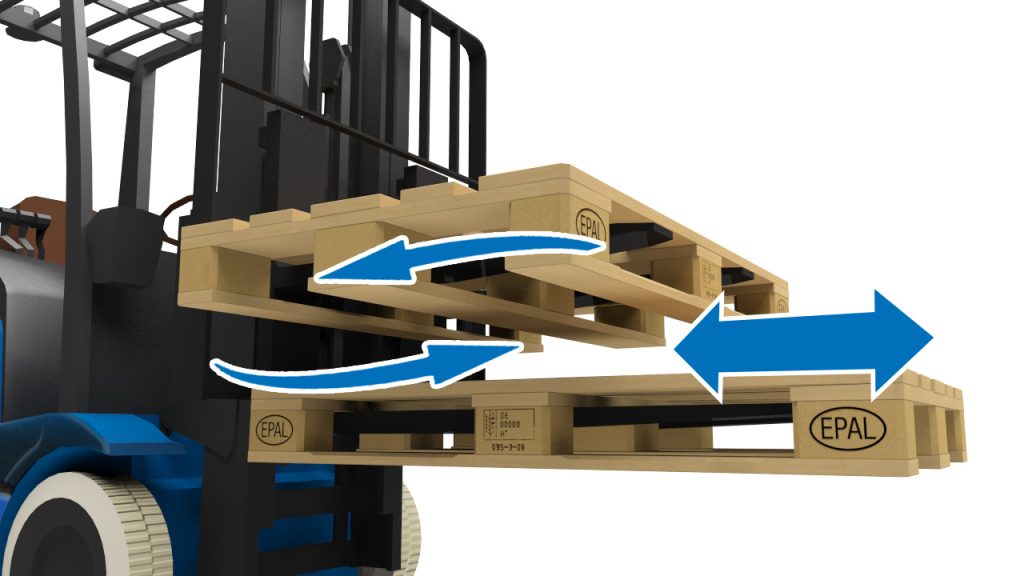

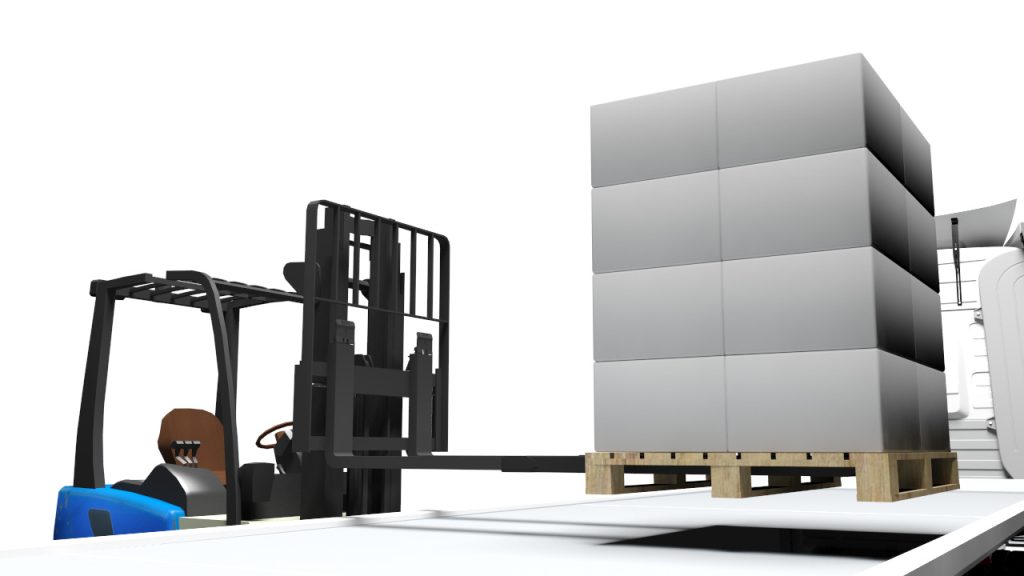

How To Prevent Damages To Pallets and Goods Handling Different Pallet Sizes

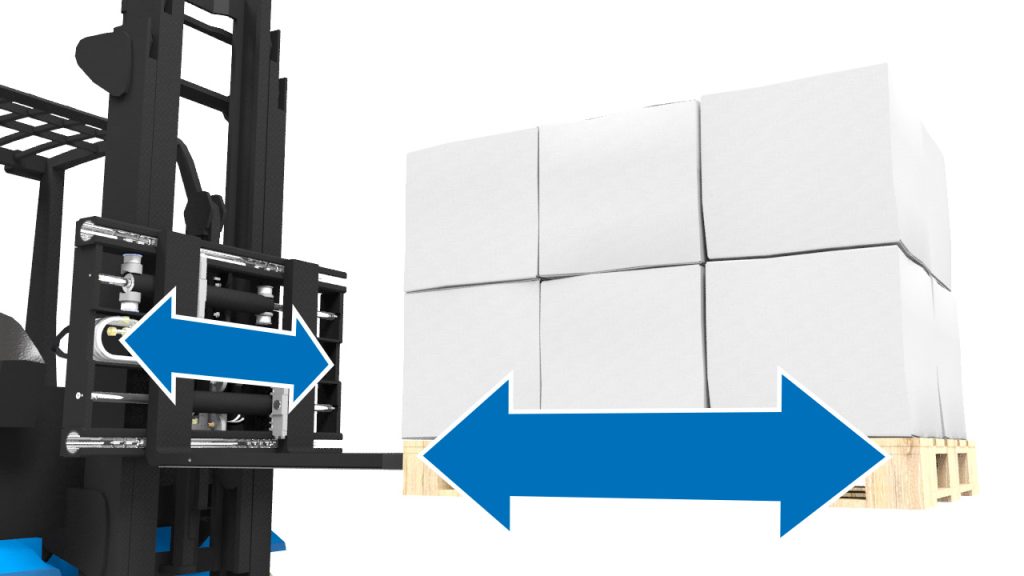

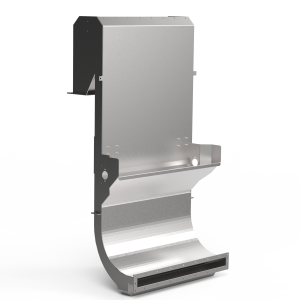

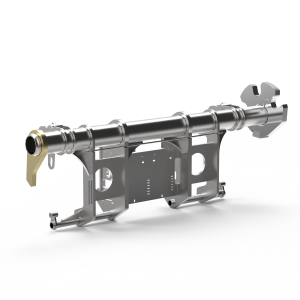

The 𝗞𝗢𝗢𝗜® 𝗥𝗲𝗮𝗰𝗵𝗖𝗼𝗻𝘁𝗿𝗼𝗹 system is transforming forklift safety and efficiency. With an 𝗶𝗻𝘁𝗲𝗹𝗹𝗶𝗴𝗲𝗻𝘁 𝗹𝗲𝗻𝗴𝘁𝗵-𝗺𝗲𝗮𝘀𝘂𝗿𝗶𝗻𝗴 𝘀𝘆𝘀𝘁𝗲𝗺 and integrated app, operators can seamlessly 𝗮𝗱𝗷𝘂𝘀𝘁 𝗳𝗼𝗿𝗸 𝗹𝗲𝗻𝗴𝘁𝗵 𝘁𝗼 𝗺𝗮𝘁𝗰𝗵 𝘃𝗮𝗿𝗶𝗼𝘂𝘀 𝗽𝗮𝗹𝗹𝗲𝘁 𝘀𝗶𝘇𝗲𝘀, enhancing precision and reducing damage risks. This innovation not only improves workflow efficiency but also boosts warehouse safety by minimizing operator error. • Different presets result […]

Read more